![]() Back to the general overview, click here.

Back to the general overview, click here.

The boat

[ Translation of the original text of 2007 in Dutch, adds and updates during the voyage ]

Overview of what was going wrong: see on the bottom of this page

In the photo-album there are a lot of pictures of the period 1994-2006 ( What happened before ).

In Kortom - Voyage and cruising notes we mention the equipment of Nehalinnia for the voyage to Greece ( charts, pilots etc ).

|

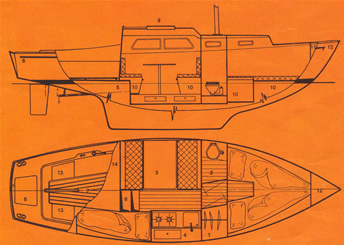

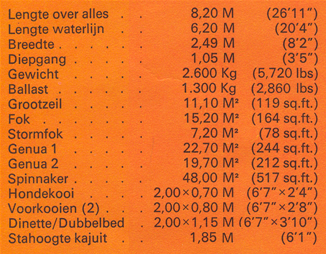

NEHALINNIA is a FELLOWSHIP 27', built by the shipyard Jachtwerf DE KLOET at KORTENHOEF, NETHERLANDS, in 1972. ( http://www.de-kloet.nl )

We buy the boat in 1994. According one part of the tradition we keep the name Nehalinnia, but during the restoration works we discover, under a thick layer of paint, the old variant Nehalennia - the name of the mother-goddess venerated in Zeeland (NL) by ancient seamen, already before the Roman occupation. Is this a double form - in ancient languages variants on vowels are relatively frequent - or a simple transcription error? More in http://en.wikipedia.org/wiki/Nehalennia ; in English https://www.livius.org/articles/religion/nehalennia/ ; in Dutch only http://www.zeeuwseankers.nl/nl-NL/verhaal/964/nehalennia-1 ; http://www.nehalennia-tempel.nl/

In no time we realise that our hope, to bring the boat in the gulf of Volos, isn't an evidence. See PROJECT.

Naive - later it will appear - but proud and brave we start some works - small gelcoat repairs essential in our opinion! - and we buy things that the former owner qualifies as gadgets ... |

|---|---|

|

|

From the the presentation documents from 1972 |

The big challenge ...

Autumn 1996. We are on the way to start the big work.

|

|

|

|

f. l. to r. : Brugge - night stop yachtclub in Beernem - arrival in Gent - Shipyard De Leie, Gent Watersportbaan

We sail the boat from Nieuwpoort to Gent. Nehalinnia will be close to our home.

|

During nine months we work hard: some days we are really down, and in the beginning we are doubting - then we continue with the courage of despair! - but later on with a lot of perseverance and endurance. There is no alternative: we have to complete this restoration successfully otherwise we will have no boat anymore ... |

|

|

|

Undressing of the superstructures, dismantling all the chandlery, the hatch, the pul- and pushpit, the guardrails and life-lines, stanchions, portholes, sanding the hull... mat, fibre glass, resin, filler, connectors, houses, cable gutters, 100m of cable, tens of cartridges of Sikaflex and primers, Airex-Herex, Moulman Teak, screws, nuts and bolts, paints and primers, varnish, sandpaper, abrasives, marine plywood, mahogany: during this winter, this spring and a large part of this summer 1997, all these materials are ordered, used, worked up ... |

For many friends, sceptically looking to us, we are reconstructing a boat around ... a dream!

|

|

|

But on July 22nd, 1997 we moor again at our berth in the yacht harbour of the VVW at Novus Portus in Nieuwpoort.

|

The boat is repainted, we have a nice teak deck, a new pulpit with integrated step and anchor gear, a complete renewed electric equipment, repainted mast and boom, new "sandwich-construction" in a large part of the roof (airex instead of balsa), new stowage in the cabin... |

|

But because the dream of Hortó is always present, the boat will need more and even bigger restoration works before we will be able to realize our project.

Year after year works on the boat ...

So later on the rigging has to be renewed: mast, boom, standing and running rigging, and sails are replaced. According the advice of Wittevrongel Sails and Rigging we keep " everything at the mast ".

A few years later we start the renovation of the hull at the new Ship Support shipyard in Nieuwpoort. Replacement of the steel/concrete ballast inside the long GRP-keel by lead, peeling/stripping of the gel coat, applying of an epoxy water barrier: all very invasive and radical works. In the space won in the keel the yard laminates a 160 litres fresh water tank, the old GRP tank in the forepeack becomes a very useful locker. A new rudder - complete with rudder stock, stuffing box and gland - should influence favourably the performances. A radar seems to be an important contribution to the safety by sudden fog, a frequent phenomenon by hot weather during the summer on the passage of the capes of the Cotentin, the Normandy peninsula, and in the Channel TTS, as the experience learnt us!

During the winter 2004-2005 we have it done to replace our small but faithful Yanmar 1GM10 engine by ... the same one: all two cylinders are just few centimetres too big for the space under the cockpit! Ship Support also installs a 50 litres flexible Vetus black water holding tank, an indispensable equipment from the ecological point of view as we think. The pipes of the self draining cockpit are enlarged, the teak seats and the duckboard replaced. We install a new NAVTEX-518/490kHz receiver: the reception is sharply improved and allows us even to receive in Nieuwpoort sometimes very clearly NAVAREA II and III messages. The icebox with Peltier-cooling system is replaced by a fridge with an energy-low Danfoss-compressor.

When departure to the Med is approaching ...

For the trip to Mediterranean Sea the yard provides, during the wintering 2006-2007, the installation of an electric anchor lass; we also have it done to replace the gas stove, the pipes and the taps; we buy a second solar panel and order Ship Support to provide adjustable supports for the unstepped mast; they repaint the hull; Nehalinnia gets new batteries, charger and diesel heater with pulsed air. We order a light stern anchor, a Fortess 16, and the improvement of the stern anchor gear.

A nice and comfortable cockpit tent enlarges the living space on our small boat; the transformation of this tent in a solid bimini provides sun protection during navigation. In the harbour or during a long anchoring, a light tarpaulin cunningly conceived by Guy Toussein will supply shadow and (relative!) coolness; we have also a wind scoop . A second tiller pilot has to contribute not only to the comfort but also to the safety. Log, sounder and anemometer were replaced in 2001 so now we replace the old VHF receiver by a GMDSS DSC-VHF-class D with ATIS; meanwhile both we obtain the SRC certificate required for this VHF receiver.

Nehalinnia can use, on the Furlex reefing system two new, different foresails: a genoa and a high aspect tri radial jib. In the opinion of our sailmaker Wittevrongel the mainsail is still in good condition, renewing is not actual; but we ask him to take al measurements for a replacement in the future. An asymmetric spinnaker and an orange fluorescent storm jib make the wardrobe complete. The mast and the standing rigging are checked meticulously.

The old dinghy that we bought second hand is replaced: after a long search at all different models and types we find a round tail 2,30m long tender, that we can easily put in one of the cockpit lockers, well equipped for our 2Hp-4T outboard.

Life jackets and life raft are serviced and controlled by the SKB station in Ostend.

[ Translation of the original text of 2007 in Dutch ]

During the voyage ...

... in France, in Menton, spring 2008:

rapidly we get problems with the Y gate of the holding tank. After replacement by an identical one, we get new problems and decide to replace it during the wintering at Menton Garavan by a hopefully more reliable solution. The new gate is custom made and consists of a short stainless A4 rounded Y pipe and two high quality ball valves; the whole gate can easily be dismantled and is not really bigger than the plastic one in which the brass shaft was coming out of the plastic housing.

for a really good fixation of left and right incoming mooring and lazy lines and the stern anchor line, we have installed a stainless A4 fairlead on starboard too.

after the crossing of France by the canals and the navigation along the French Med coast we have to replace the water pump of the direct cooled Yanmar 1GM10 due to too frequent leaks; we service the old pump - replacement of oil seals and the shaft- and keep it as spare part till we bring a new one from Nieuwpoort at the autumn 2008.

we get the by Ship Support built passerelle adapted: double fixation system: a pivot with articulation for the pulpit, an U stainless profile for fixation on the ladder or on the pushpit.

for the navigation with electronic charts, we buy a 435i Raymarine plotter to limit the use of our laptop during sailing, and for the reception of weather forecasts, a WIBE receiver - but the results (and particularly the reception of weather charts) will be very disappointing. The 3G internet connection on board, which we have since Elba, constitutes in our opinion the best solution ( read more about this in Kortom/Cruising notes )

... in Greece, at Lefkas:

September 2008: - our laptop is definitively out of use, we replace it by a Toshiba Tecra, more vibration- and shockproof but only available in Greece with an international QWERTY keyboard and XP + Vista professional international versions (English US & UK) - or Greek! -; this is less convenient for certain signs and special characters, part. in French, such as accents, cedilla etc.)

Spring 2009: - when hauling out after the wintering 2008-09, we notice that on the hull - which we had Ship Support repainted before our departure in 2007- the paint is coming off at some places on the waterline. Is this the effect of the prolonged contact with the water, or a to heavy high pressure cleaning, or a paint-sanding-adhesion problem? Ship Support in Nieuwpoort and Paleros at Lefkas give different explanations. Due to the urgency - we have to haul in in two days - we have the small repairs done by Paleros.

- for the stern anchor warp of the Fortess 16 we have a stainless steel A4 box made by Steel Marine (" Phil the Steel ") in Nidri, fixed on the pushpit; 4/5 of the 40 m long warp in it, the leaded part is coiled up around the anchor shank and secured by a rope.

Spring and summer 2010: - during our stop in Reggio di Calabria, two years ago, we had to replace our batteries then only one year old. But now we notice that these batteries should be, again, replaced soon. The installation which during almost fifteen years gave satisfaction does not correspond any more to our use: we thus decide to modify our system which includes only two batteries of 80Ah in parallel, a charger and a switch. In the magazine Boat Owner the renovation of the electric installation of a Vancouver 27 was clearly explained. We decide to be inspired by it and to ask for the execution Yacht Electrics (mobile 6938569143), recommended by many sailors here. Two days later, to our full satisfaction, the renewed system is in use: besides our Dolphin battery charger, the switch and two new service batteries ( 2x90Ah) we have now an (apart) engine battery ( 62Ah), diode, shunt, Sterling Power advanced alternator regulator and power management panel.

Winter 2011: unexpected works on the underwater hull.

We have spent more than four months in Belgium and will return to Lefkas at the end of March: this is by no means a deliberated choice but the consequence of totally unexpected works on the underwater hull of our boat.

The story of a big frustration ...

As we have already mentioned on this page we made realize important and expensive renovation works on the hull of our sailing boat: with the aim of the trip to the Mediterranean Sea some years later, the ShipSupport yard in Nieuwpoort applied a protection treatment against osmosis.

We knew that during the voyage the boat would stay for a long time in the water and would winter probably afloat. We wanted to spend the winter on board in Menton and we did not plan to leave the boat during several months in Greece for spending the winters in Nieuwpoort, this being not at all part of our project!

In the Mediterranean Sea (and particularly in France and in Italy) boats stay, for the great majority, afloat all year long - except a few days, necessary for maintenance works- most of the harbours having no possibilities of wintering on the hard. In Greece wintering ashore constitutes practically no problem because there are a lot of parking places for boats depending from the numerous (rather small) boatyards or from the (rare) marinas. But, living on our boat on the hard is not really an option ...

After this treatment our boat would be well protected and would thus bear without problems a prolonged stay afloat, appropriate for our long trip …

The original ballast - concrete and steel - in the long keel is replaced by lead fixed by a special resin, a new water tank is installed in the free space and a complete new rudder system is built.

According to the conditions of the three years warranty, the boat is checked every year by ShipSupport during the winter storage in the shed, when we make them make the other works until our departure for the Mediterranean Sea in 2007.

Then the boat winters afloat at MENTON-GARAVAN F ( 2007-2008 ) and at LEFKAS-MARINA GR ( 2008-2009 ).

During the hauling out for the maintenance we notice nothing of abnormal except that - in March 2009 - the boot-topping comes off on about twenty centimetres during the the high pressure cleaning of the hull. This small repair is made at Lefkas and we inform ShipSupport who has repainted the hull and so also the waterline before our departure.

But when at the end of April 2010 we haul out the boat, we find, scattered on all the hull, big blisters. The cleaning of the hull has to be done carefully because in numerous places the epoxy is completely coming off. We ask a British surveyor for advice. He wants to know what products the yard has used but above all he wants to know how many times the hull was rinsed after the peeling of the gelcoat and before the epoxy was put during the anti-osmosis treatment of 2003.

To be able to give him answers we then call ShipSupport. We are not really helped by their answers: the products are mentioned on the invoices of 2003 (but we do not have them here in Greece!); they had rinsed the hull certainly and at least once and the inside of the keel, after removing the ballast, even several times; and, " the boat was dry when the treatment started ". We get also some reassuring words: " Van een paar blazen, daarvan zal ie wel niet zinken! Jullie kunnen gerust zo nog een paar jaar doorvaren " [trans. Due to a few blisters, the boat will not sink! You can continue sailing in complete peace during some years ".].

We are really not reassured: how could we apply the anti-fouling during the coming hauling out on an undercoat which is coming off? Furthermore It seems impossible - unacceptable - that a treated underwater hull yearly checked according to the conditions of warranty during the winter storage inside the ShipSupport yard (2003-2007), gets a big problem after only 3 years afloat (2010).

As we are in the beginning of the season and as we have reserved the hard standing of the boat in Lefkas Marina only for one week - the time for spring maintenance - we decided in agreement with the surveyor, to paint the antifouling as well as possible. Then we launch the boat again. At the end of the season we will haul out again and in meanwhile we will see the different possibilities.

Having sent by email pictures of the hull to ShipSupport - an email for which we get no other answer than an acknowledgement of receipt -, we have by the intervention of the surveyor an appointment with the British owner of Ionian Composites-Ionian Glass fibre Repair yard, specialized in this kind of GRP problems and which enjoys in Lefkas and more of an excellent reputation, e.g. by the numerous foreign community.

According to the surveyor and Ionian Composites-Ionian Glass fibre Repair expert, there are two very likely hypotheses to explain the problem: either a totally insufficient frequency of rinsing of the polyester after the peeling of the gelcoat (the most frequent cause of second recurrence), or a problem during the treatment ( incompatibility of the used products, condensation just before the first coat a.o. ). Nevertheless both underline that they can say this so far as it's certain that the hull was really dry enough when the treatment was started, what is declared by ShipSupport.

We ask Ionian Composites-IGR to give us an estimation for the works and we also call again ShipSupport asking a price proposition in case we would make redo the works after our return to Nieuwpoort. We also try to obtain more information about the treatment of 2003. Now we hear that the hull would have been rinsed "several times" [cit. Dutch. "Een paar keer gespoeld was geweest"]. Later, reading in the estimation which ShipSupport sends us by email we are very surprised: " regular rinsing and washing with soap 16 H in 40 euros / hour, non-inclusive VAT " [cit. Dutch " Regelmatig spoelen in afwassen puts zeep: 16 U aan 40 euro / uur, excl. BTW "] ...

October 20th, again, we haul out the boat. We see that the the problem is a lot worse: it is now not anymore possible to clean the hull by high pressure without the antifouling and epoxy coats coming off on important surfaces. We are afraid that it will get worse year by year (or even month by month?) and we don't know how we could paint a new ( holding ) anti-fouling.

Then, with a heavy heart spending the money for the second time without having something really other - we resign to redo the works, in Lefkas by Ionian Composites-IGR ...

Both, our surveyor and the GRP specialist examine the boat before our departure for Belgium on October 25th and they confirm their hypotheses.

Back in Belgium we contact Ronny Nollet from ShipSupport. We redo - verbally this time - the tour of the problem. Now it appears that the hull) has been " all the same, rinsed several times " [cit. Dutch " Toch zeker verscheidene keren "]. To the final question if all this seem normal to him, we get this following answer: " No, but I shall contact the supplier of the products; I have never seen a similar thing. " [Cit. Dutch " Nee, maar ik zal contact opnemen met de leverancier van de producten; ik heb zo' n geval nog nooit meegemaakt."]

One week later, the yard gives us the answers of the supplier, as their own conclusion too:

" The yard made the job well " ( was this "expert" present? ) - [and this are the] possible causes of the problem: 1. " Because of the long sailing the boat became more " lung ", so that the harder epoxy gets loose from the hull " ( thus some more years of sailing and the boat will disintegrate totally, quite like all these other cruising boats, a worldwide disaster?! Let us urgently inform all about this so precious expertise ) 2. " Travelling in warmer waters " ( so, let's all sail to Iceland and don't forget the global warming and the unexpected consequences for boats !? ) 3. " The old polyester can provoke a reaction with the [modern] paint systems " ( let us follow a little this reasoning: why then have they treated our boat in 2003? but now all the shipyards the world which knowing this excellent expertise urgently have to stop treatments on older boats, and because only the new boats can be treated, it will be a terrible economic loss, all these yards closing their doors due to the lack of customers ! ?).

We are at that moment at the beginning of December.

Since then we heard nothing more on behalf of ShipSupport.

|

||

Winter 2011, on the hard at Lefkas Marina, Nehalinnia sanded again: only seven years after the treatment by ShipSupport in Nieuwpoort (B), for a time back to the start. Now it's waiting for the finishing works by Ionian Composites-Ionian Glassfibre Repair of Leslie Wood. |

01.05.11 Nehalinnia is moored since last Tuesday - 26th April - at her berth in Lefkas Marina.

Schematically works went on like this ( Leslie Wood - Ionian Composites-Ionian Glassfibre Repair - emailed us during our stay in Belgium news and pictures, completed by his verbal comments when we arrived ):

|

- third week of November 2010: sanding of the underwater hull and removing of the epoxy filler of the treatment in 2003 finished; Leslie Wood reports the easy removing due to the poor adherence, the epoxy filler is no longer bonded to the glass fibre, stripping it there is a lot of solvent coming out, and that the laminate is in good condition and not wet; he notes that the laminate has still the (to smooth) traces of the gelcoat peeling (2003); - to remove any rests of solvents and salts the area was pressure washed several times a week over a period of two months (January 2011); rain and wind are participating to the job; - the temperature and the strong winds over Lefkas this winter ( Keith Rimmer - s/y Sea Trek - reported one time more than 50 kn on the boat's anemometer!) did dry our boat well; regularly the moisture is measured; - end of March and April 2011: the bottom is filled using a filler made using DOW 321 Epoxy ; then faired into shape; after this, five layers of DOW 321 resin is applied, followed by four coats of International Gelshield Epoxy Primer; after that six layers of Coppercoat anti-fouling; the blue waterline was little higher painted on the epoxy barrier. - Leslie Wood has also renewed all skin fittings and seacocks below the waterline (18 en 23 april 2011) ===> We have been well informed about the progress of the works; Penny and Keith (s/y Sea Trek) and Christine and Guy (s/y M.Balthazar) have sent us pictures too; Maureen and Mark Wicherley were taking care of our boat. |

26 th April 2011 10H30: Nehalinnia ready to be launched

May 2011: Besides the important routine maintenance prescribed after 1200 engine hours ( e.h.) again we have to replace the direct cooling pump, after 593 e.h. (on a total of 1178) due drain hole leaking, also making rusty the high pressure oil pipe. By experience we know that replacing the SPI-seals without replacing the small shaft does not bring a solution because the slightest wear on the shaft will still make leak the pump. The replacement of the seals is rather difficult without the appropriate tools and a workshop. That is why we always have a spare pump ready for use. Our engine was installed in 2005 and counts now 1178 hours. The pump was replaced a first time in 2008 after 585 e.h. just before we left Menton (F), thus after the crossing of France by the canals and the sailing along the French Med coast ( see here above ). We have also to replace the high pressure oil pipe (in 2006 some rusty traces have already appeared which were treated by ShipSupport using a special paint. Replacement also of the exhaust mixing elbow due to rather sudden rust and light oozing. We are worrying about the quality of this new Yanmar 1GM10 engine whom we made install six years ago in replacement of the identical which was then 17 years old. According to the ShipSupport yard there was due to the lack of space no two cylinders with (indirect) fresh water cooling - intercooler - on the market that could be installed. We thought of having bought and received all spare parts we needed - from ShipSupport on our departure in 2007, and during the last winter from Turbo's Hoet until Simon Trippier, the British technician who runs Sivota Yacht Services (MOB 0030.6946580785), notices that some gaskets are missing. They were immediately ordered at Yanmar Athens - and at Turbo's Hoet in Nieuwpoort when we were thinking that the Greek delivery could be longer. As soon as the parts arrived at Lefkas Simon came to assemble and service the engine.

What was going wrong despite scrupulous and regular maintenance: |

HULL |

underwater hull: osmosis protection and epoxycoating 2003 neededc a full refit at Lefkas (Gr) by Leslie Wood ( Ionian Composites-Ionian Glassfibre Repair in 2010-11 |

1st treatment 2003 after gelcoatpeeling and drying by Ship Support Nieuwpoort B |

|

ENGINE (2005) Yanmar 1GM10 |

waterpump: 2008 e.h 0585 replaced (Menton F) leakage / 2011 e.h. 1178 replaced, (Lefkas Gr) leakage / 2014 e.h. 2233 replaced (Pefkakia, Volos, Gr) leakage |

this new engine was installed by Ship Support Nieuwpoort in 2005; they serviced and checked the engine in 2005/2006 and in 2006/2007 before the start of the voyage enginehours (e.h.) when starting voyage in July 2007: 0346 |

|

05/2011 Lefkas, Simon Trippier, Sivota Yacht Service:lubrication pipe - e.h 1178: replaced, (Lefkas Gr) rust, passing under waterpump |

|||

winter 2011/12 ( Lefkas, Simon Trippier, Sivota Yacht Service): -complete service (refit & wiring) of the starter and the alternator -removing the too heavy and partly obstr. exhaust oneway valve - due to increasing shaft vibration, after check of the complete drive system: new propeller shaft (worn where tube has rubbed), new flexible coupling, gland, new cutless bearings for sterntube and P bracket, new exhaust pipe with Vetus one-way-through-hull |

|||

ELECTRICITY |

both batteries (new 2007 Nieuwpoort): 2008 both replaced (Reggio di Calabria I) dead / 2010 replaced both batteries (bad charge) + full refit charge & monit. system + cabels + inst. engine battery + adap. conn. charger & cabelconn. windlass ( Lefkas) Spring 2012: (Lefkas, Simon Trippier, Sivota Yacht Service):new charger system check due too bad charge, repl. diode bridge (new 2010) by Sterlingsplitter 2013: repl. engine battery and start button; 2014: repl. service batteries. |

electric system was already checked and partly adapted in 2005 and 2006/2007 byj Ship Support in Nieuwpoort |

|

ELECTRONICS |

Wibe-receiver: mainly poor results, no weather charts |

installed Menton F 2008 |

|

HOLDING TANK |

3-way tap ALPA: 2 times replaced 2007 & 2008; second time replaced in 2008 now by a custom made stainless tap (Menton F) |

|

installed 2006 |

PASSEREL |

important adaptation at Menton F (2008) of the in Nieuwpoort custom made passerel by ShipSupport unpractical due to the lack of a stable fastening system |

solution: a pivot with articulation for the pulpit, an U stainless profile for fixation on the ladder or on the pushpit |

LESSONS LEARNED |

- about the treatment of the hull: ask details about treatment by several yards, compare, and follow the differents stages of the proces - about the replacement of the engine: it seems that the replacement of the old small Yanmar one cylinder in-board engine by the same one has not been the right choice; it appears also that not all possibilities for the installation of a fresh water cooled engine were not seriously explored - despite the limited space - as we were told by numerous technicians during our voyage. The Yanmar 1GM10 seawater cooling system is one of our concerns. After using the engine we rinse with fresh water ( by the water strainer ) and with antirust/antifreeze before winter storage. Advice: look for possibilities more by yourself, ask more different yards and engineers! - about the spare-parts: check every part when buying, look into the Assembly and disassembly manual and the Spare parts lists, don't trust prepackeds |